Abstract

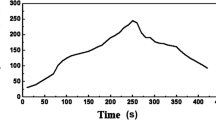

In this work, friction stir soldering (FSS) as a new approach for fabrication of copper/copper lap joints was introduced. This process is principally based on the friction stir processing (FSP) that can be performed using FSP tools with and without pin on the top sheet. In the present study, Pb-Sn foil was used as a solder which would be melted and then extruded in the area between the copper sheets during FSS process. This process was carried out using tools with and without pin at various rotation speeds of 1200, 1400, and 1600 rpm and traverse speed of 32 mm/min. Also, the same joint was fabricated using furnace soldering to compare the mechanical properties obtained with FSS and furnace soldering processes. It was observed that FSS possesses some advantages over the conventional furnace soldering process including the formation of more bond area at the interface corresponding to the higher fracture load of FSS joints compared with furnace soldering one. Moreover, it was concluded that the thickness of intermetallic compounds (IMCs) and the formation of voids at the joint interface were the predominant factor determining the mechanical properties of the FSS joints produced by FSS tool with and without pin, respectively. The microstructural examinations revealed that Cu-Sn IMCs of Cu3Sn and Cu6Sn5 were formed at the joint interface. It was observed that the FSS joint produced by tool with pin experienced the more peak temperature in comparison with that produced by pin-free tool. This may lead to the formation of thicker IMCs at the interface. Of course, the thickness of IMCs can be controlled by choosing proper FSS parameters, especially the rotation speed of the tool.

Similar content being viewed by others

References

L. Liming, W. Shengxi, and Z. Limin, Study on the Dissimilar Magnesium Alloy and Copper Lap Joint by TIG Welding, Mater. Sci. Eng. A, 2008, 476, p 206–209

M. Watanabe and S. Kumai, Interfacial Morphology of Magnetic Pulse Welded Aluminum/Aluminum and Copper/Copper Lap Joints, Mater. Trans., 2009, 50, p 286–292

H. Bisadi, A. Tavakoli, M.T. Sangsaraki, and K.T. Sangsaraki, The Influences of Rotational and Welding Speeds on Microstructures and Mechanical Properties of Friction Stir Welded Al5083 and Commercially Pure Copper Sheets Lap Joints, Mater. Des., 2013, 43, p 80–88

I. Galvão, D. Verdera, D. Gesto, A. Loureiro, and D.M. Rodrigues, Influence of Aluminium Alloy Type on Dissimilar Friction Stir Lap Welding of Aluminium to Copper, J. Mater. Process. Technol., 2013, 213, p 1920–1928

Y.L. Shabtay, M. Ainali, and A. Lea, New Brazing Processes Using Anneal-Resistant Copper and Brass Alloys, Mater. Des., 2004, 25, p 83–89

M.G. Affendy and A.A. Mohamad, Effects of Crosshead Speeds on Solder Strength of Cu/Sn-9Zn/Cu Lap Joints, J. King Saud Univ., 2013, doi:10.1016/j.jksues.2013.09.003

S.-J. Jeon, J.-W. Kim, B. Lee, H.-J. Lee, S.-B. Jung, S. Hyun, and H.-J. Lee, Evaluation of Drop Reliability of Sn-37Pb Solder/Cu Joints Using a High Speed Lap-Shear Test, Microelectr. Eng., 2012, 91, p 147–153

H.-T. Lee, H.-S. Lin, C.-S. Lee, and P.-W. Chen, Reliability of Sn-Ag-Sb Lead-Free Solder Joints, Mater. Sci. Eng. A, 2005, 407, p 36–44

M.S. Khorrami, M. Kazeminezhad, and A.H. Kokabi, Thermal Stability During Annealing of Friction Stir Welded Aluminum Sheet Produced by Constrained Groove Pressing, Mater. Des., 2013, 45, p 222–227

E. Lertora, Comparison of AA 2024 T3 Friction Stir Welded and Riveted Overlap Joints with the Addition of a Pressurization Test, Mater. Des., 2013, 49, p 259–266

J. Shen, D. Min, and D. Wang, Effects of Heating Process on the Microstructures and Tensile Properties of Friction Stir Spot Welded AZ31 Magnesium Alloy Plates, Mater. Des., 2011, 32, p 5033–5037

G.-F. Zhang, W. Su, J. Zhang, Z.-X. Wei, and J.-X. Zhang, Effects of Shoulder on Interfacial Bonding During Friction Stir Lap Welding of Aluminum Thin Sheets Using Tool Without Pin, Trans. Nonferrous Metals Soc. China, 2010, 20, p 2223–2228

Y.-H. Lee and H.-T. Lee, Shear Strength and Interfacial Microstructure of Sn-Ag-xNi/Cu Single Shear Lap Solder Joints, Mater. Sci. Eng. A, 2007, 444, p 75–83

S.Y. Chang, C.C. Jain, T.H. Chuang, L.P. Feng, and L.C. Tsao, Effect of Addition of TiO2 Nanoparticles on the Microstructure, Microhardness and Interfacial Reactions of Sn3.5AgXCu Solder, Mater. Des., 2011, 32, p 4720–4727

A.A. El-Daly, A.E. Hammad, G.S. Al-Ganainy, and A.A. Ibrahiem, Design of Lead-Free Candidate Alloys for Low-Temperature Soldering Applications Based on the Hypoeutectic Sn-6.5Zn Alloy, Mater. Des., 2014, 56, p 594–603

J.F. Li, P.A. Agyakwa, and C.M. Johnson, Interfacial Reaction in Cu/Sn/Cu System During the Transient Liquid Phase Soldering process, Acta Mater., 2011, 59, p 1198–1211

G. Zhang, W. Su, J. Zhang, and Z. Wei, Friction Stir Brazing: A Novel Process for Fabricating Al/Steel Layered Composite and for Dissimilar Joining of Al to Steel, Metall. Mater. Trans. A, 2011, 42, p 2850–2861

J.-Q. Su, T.W. Nelson, T.R. McNelley, and R.S. Mishra, Development of Nanocrystalline Structure in Cu During Friction Stir Processing (FSP), Mater. Sci. Eng. A, 2011, 528, p 5458–5464

G. Humpston and D.M. Jacobson, Principles of Soldering and Brazing, ASM International, USA, 1996

M. Barmouz, M.K.B. Givi, and J. Jafari, Evaluation of Tensile Deformation Properties of Friction Stir Processed Pure Copper: Effect of Processing Parameters and Pass Number, J. Mater. Eng. Perform., 2014, 23, p 101–107

P. Xue, G.M. Xie, B.L. Xiao, Z.Y. Ma, and L. Geng, Effect of Heat Input Conditions on Microstructure and Mechanical Properties of Friction-Stir-Welded Pure Copper, Metall. Mater. Trans. A, 2010, 41, p 2010–2021

J.J. Shen, H.J. Liu, and F. Cui, Effect of Welding Speed on Microstructure and Mechanical Properties of Friction Stir Welded Copper, Mater. Des., 2010, 31, p 3937–3942

A.C.K. So, Y.C. Chan, and J.K.L. Lai, Aging Studies of Cu-Sn Intermetallic Compounds in Annealed Surface Mount Solder Joints, IEEE Trans. Compon. Packag. Manufact. Technol. B, 1997, 20, p 161–166

S.-J. Jeon, S. Hyun, H.-J. Lee, J.-W. Kim, S.-S. Ha, J.-W. Yoon, S.-B. Jung, and H.-J. Lee, Mechanical Reliability Evaluation of Sn-37Pb Solder Joint Using High Speed Lap-Shear Test, Microelectr. Eng., 2008, 85, p 1967–1970

Acknowledgment

The authors wish to thank the research board of Sharif University of Technology for the provision of the research facilities used in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarkari Khorrami, M., Kokabi, A.H. & Movahedi, M. Study on Joint Interface and Mechanical Properties of Cu/Pb-Sn/Cu Lap Joint Produced by Friction Stir Soldering Process. J. of Materi Eng and Perform 24, 2158–2169 (2015). https://doi.org/10.1007/s11665-015-1489-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1489-y